We Service Internationally!

Exploring Particle Size Reduction and Milling Media

Material processing is a vital part of the manufacturing process that spans across several various industries. Using a custom ball mill transforms coarse raw materials into finer, more usable particulates for further use. Central to this process is the use of effective milling media. Whether you’re new to ball mill processing or a seasoned industry insider, you might have the question, "What are grinding balls?"

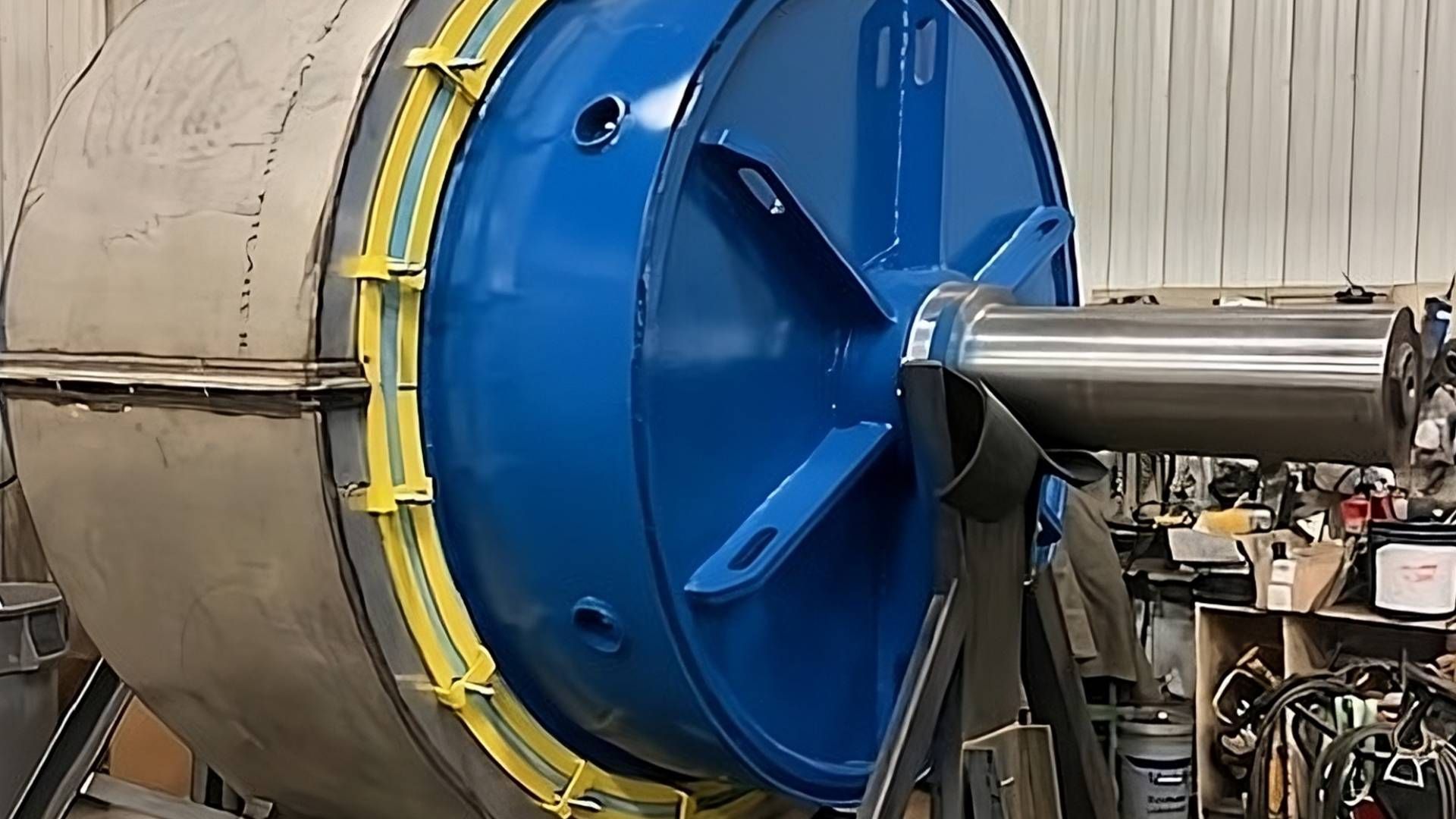

At Economy Ball Mill, based in Tollesboro, Kentucky, we serve a range of industries across the USA and worldwide, providing custom ball mill solutions tailored to our clients’ specific material processing needs. Let’s dive into the differences of different types of milling media and their role in particle size reduction for use in our custom ball mills.

What are Grinding Balls?

A ball mill employs grinding balls made from various materials to achieve a specific level of size reduction. The selection of these grinding balls is critical and depends on the medium which your business is processing, impacting everything from the overall efficiency of the ball mill to the quality and size of the end product.

Grinding balls are the workhorses of the milling process, pulverizing materials within the ball mill. Their effectiveness is defined by their size, material, and composition, which should be chosen considering the grinding style, material's nature and the desired final product. The quality of these balls directly correlates with the uniformity of the particle size reduction and the overall efficiency of the milling operation.

Some questions to consider are:

- Are you performing wet or dry ball mill grinding?

- How coarse or fine do you want your final product to be?

What Are Grinding Balls Made From?

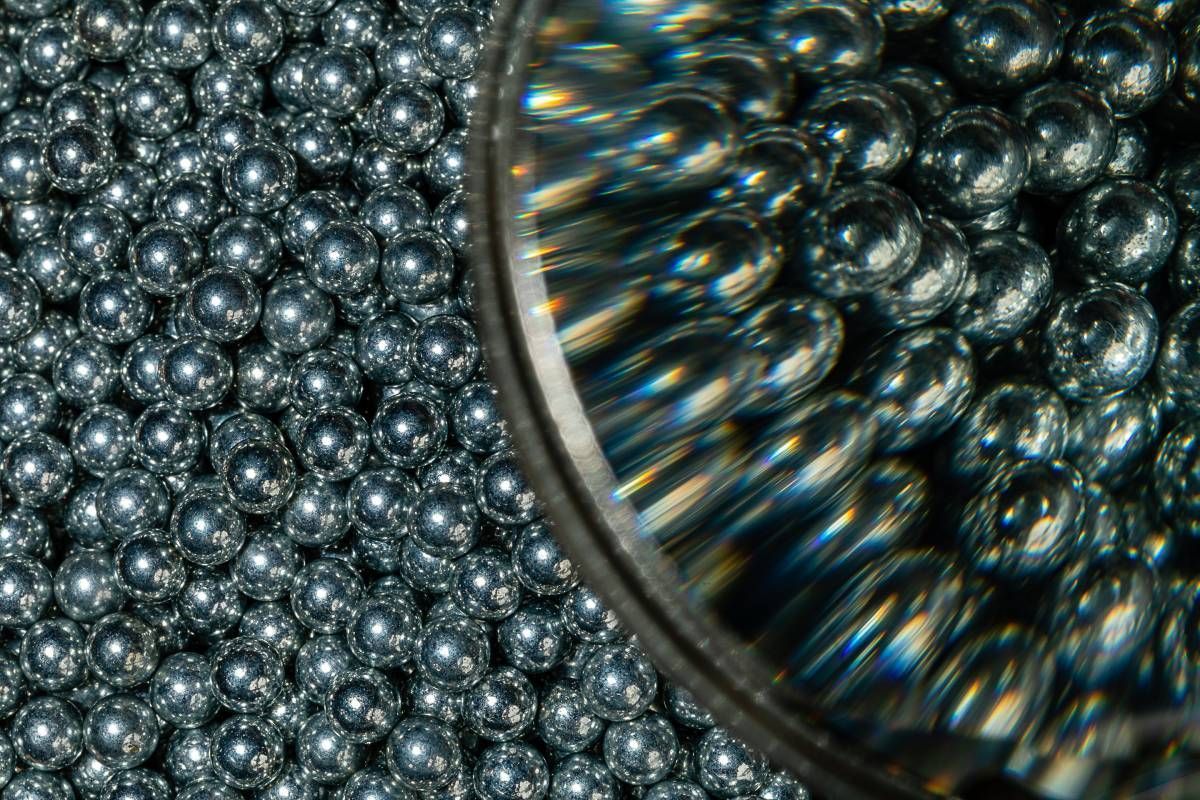

Our understanding of the unique nature of each material processing project has led us to offer custom solutions for business owners interested in milling media. This means our ball mills and milling media are designed to handle any specific requirements, ensuring that we can meet the precise requirements of our clients. You can choose grinding balls made from:

- Chrome steel balls

- Forged steel balls

- Stainless steel balls

- Ceramic balls

- Glass or plastics, for special grinding purposes

Why Choose Specific Milling Media

The choice of milling media is not arbitrary. The size of the grinding balls influences the final particle size; smaller balls are better for achieving a finer product. Similarly, the material of the balls affects their impact strength and durability, with metal balls being preferable for harder and denser materials while plastic balls may be the perfect choice for some lower-impact applications. These choices are critical for maintaining the ball mill's integrity and performance, and at Economy Ball Mill, we can help you decide which option will work best for your processing needs.

Economy Ball Mill’s Edge

When you work with our team at Economy Ball Mill, you can take advantage of several benefits. Our custom solutions ensure that your specific material processing needs are precisely met. Our expertise in the field, backed by high-quality milling media and custom-made devices, guarantees optimal milling efficiency and performance, and we are ready to deliver results from day one.

Furthermore, our location allows us to efficiently serve industries across the United States and worldwide. Our commitment to excellence and our thorough understanding of our clients’ material processing needs position us as a trusted partner for businesses seeking effective, reliable milling solutions.

Let Us Elevate Your Milling Efficiency and Performance

Whether you’re new to ball mill grinding or a seasoned professional in the manufacturing industry, the choice of milling media in the particle size reduction process is a critical decision that impacts your business’s efficiency, product quality, and, ultimately, your bottom line. At Economy Ball Mill, we leverage our expertise to provide custom, high-quality milling solutions and grinding balls that meet your needs.

Our dedication to excellence ensures that we deliver unparalleled efficiency and performance, making Economy Ball Mill the ideal choice for any industry seeking advanced material processing solutions. For more information, contact us online or call (606) 798-5724 today. Let us help you achieve your material processing goals with our tailored solutions and expert guidance.

All Rights Reserved | JSB Industrial Solutions, INC

Website Design by Creekmore Marketing