Walking Through the Ball Milling Process

Ball mills are a cornerstone of material processing at scale. They are used across various sectors, including manufacturing, biochemical production, pharmaceuticals, cosmetics, and food processing, among many others. Their purpose? To efficiently reduce materials into smaller particles for further processing, like fine powders or pastes.

At Economy Ball Mill, our experienced team knows all about how to create a ball milling process that will work perfectly for your enterprise needs. Let us walk you through the mechanics of ball mills, detailing how they transform coarse materials into finely milled products.

The Ball Milling Process

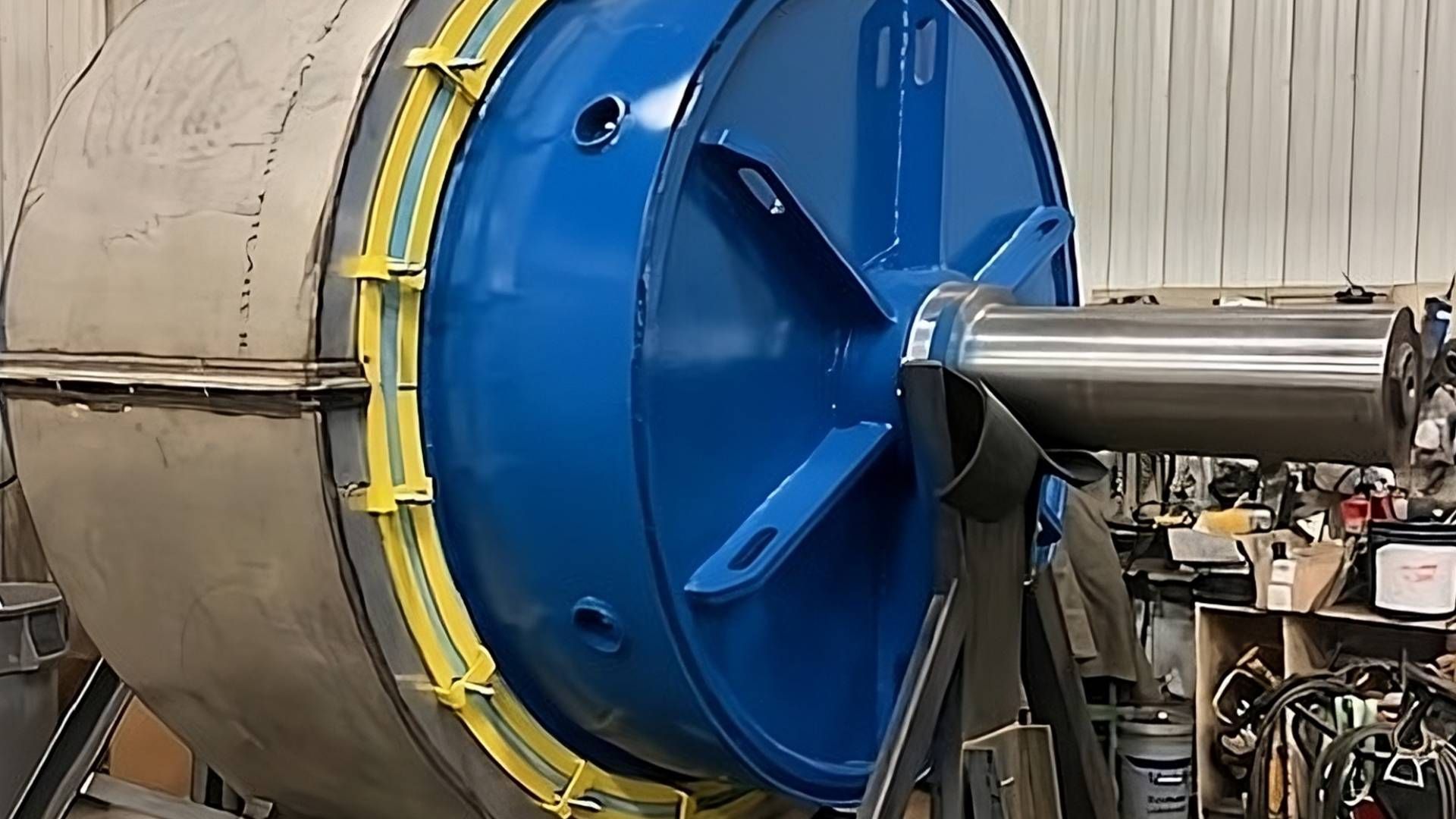

The process begins when the material to be ground is loaded into the mill's drum. This can be anything from precious metals and ores to fly ash from coal processing to chemicals and other raw materials.

Depending on the application, the ball mill drum is filled with grinding bodies of different sizes and materials to achieve the desired grinding result.

Once loaded, the drum starts to rotate, creating a centrifugal force that lifts the grinding balls to a certain height before gravity makes them fall on the material's surface and mix material. The impact, friction, and collision of the grinding balls among themselves and the material lead to a consistent grinding action. The motion is usually set up so that the balls drop near the drum's top, maximizing the crushing force.

Three Factors Influencing the Ball Milling Process

Several variables must be carefully managed to optimize the ball milling process's effectiveness. Here are three critical factors that significantly influence the outcomes of your milling operations, each playing an important role in milling efficiency and the quality of the final product:

- Grinding Media Size and Weight: The size and weight of the grinding media can dramatically influence the milling action. Balls made of more dense media can produce a coarse grind, while lighter balls lead to a finer grind. The choice of media depends on the material being milled and the desired particle size.

- Material Density: Harder and more dense materials are harder to grind and require more capacity in your ball milling equipment. Heavier and denser material also require more time and energy to grind.

- Barrel Grinding Speed: The speed at which the mill drum rotates is another critical factor in the ball milling process. If the drum rotates too slowly, the grinding balls don't create enough energy to fracture the large particles. Conversely, a speed that is too fast can cause excessive ball movement, where the balls remain flush with the drum walls due to centrifugal force, reducing the grinding efficiency.

- Milling Duration: The length of time the materials remain in the mill affects the fineness of the grind. Longer milling times allow more opportunities for the balls to strike the material, resulting in a finer product. However, over-milling can lead to excessive particle size reduction and energy waste.

Find Quality Ball Milling Equipment at Economy Ball Mill

Ball mills are indispensable tools in the material processing industry. They harness the power of motion to transform coarse materials into finely ground products. Located in Tollesboro, Kentucky, our team at Economy Ball Mill is your go-to source for all types of ball milling equipment. Our expertise and quality products are available across the USA, Canada, the UK, and worldwide.

Whether you need a standard size or a custom-built ball mill to meet your specific needs, our team is here to assist. Contact us online or call (606) 798-5724 to learn more about how our ball mills can improve your production processes. Let us help you achieve precise material grinding with our reliable milling solutions.