Economy Ball Mill, a division of JSB Industrial Solutions, Inc. manufactures Ball Mills that are diverse in applications and uses. Since we are an OEM and our product line has been around for over 50 years, we can provide the experience and knowledge to enhance your process capabilities by applying our procedural based manufacturing methods to your process knowledge. Partnering with our clientele is our passion, so we know we exceed your expectations with your finished machinery.

We've worked with various industries to provide equipment for processing:

- Abrasives

- Advanced Ceramics

- Agricultural Chemicals

- Artificial Bone Compounds

- Biologicals

- Carbides

- Carbon

- Catalysts

- Ceramics

- Coatings

- Cosmetics

- Dental Ceramics

- Dyes

- Flame Retardants

- Fungicides

- Glass Frit

- Glazes

- Herbicides

- Ink

- Lacquer

- Limestone

- Metal Oxides

- Mineral Assay

- Oxides

- Oxidizers

- Pesticides

- Pharmaceuticals

- Pigments

- Plastics

- Polishing Compounds

- Polymers

- Powdered Metals

- Precious Metals

- Precipitates

- Rare Earth Minerals

- Resins

- Semiconductor Compounds

- Silicates

- Solar Cell Materials

- Titanium Dioxide

- Toners

- Tungsten Carbide

- Varnishes

- White Ware

"...Shane Wallingford and his team have become our go to supplier for ball mills and ball mill lid replacements. They have worked closely with our maintenance staff to provide detailed drawings and are quick to make requested modifications to said drawings when needed..."

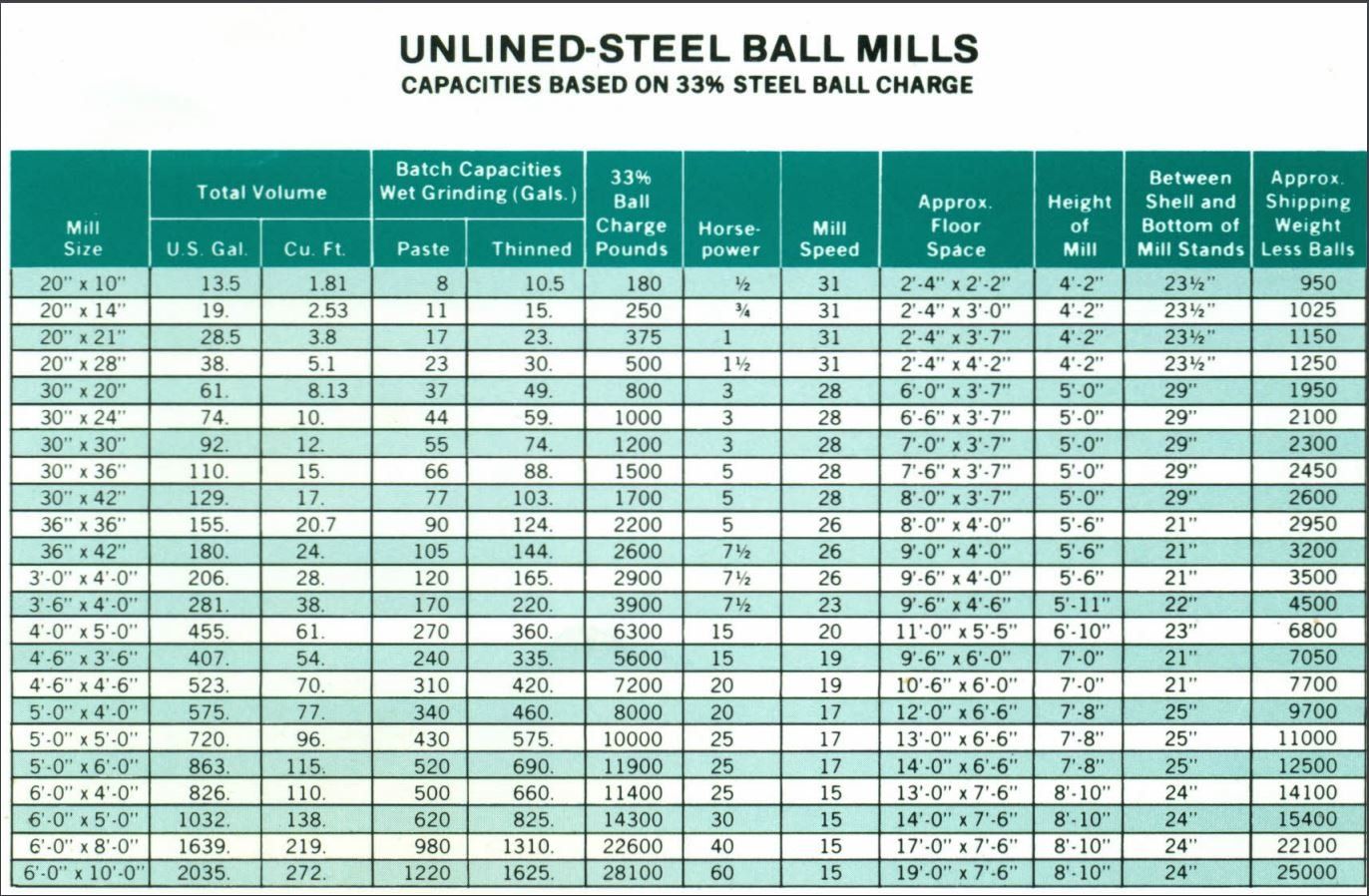

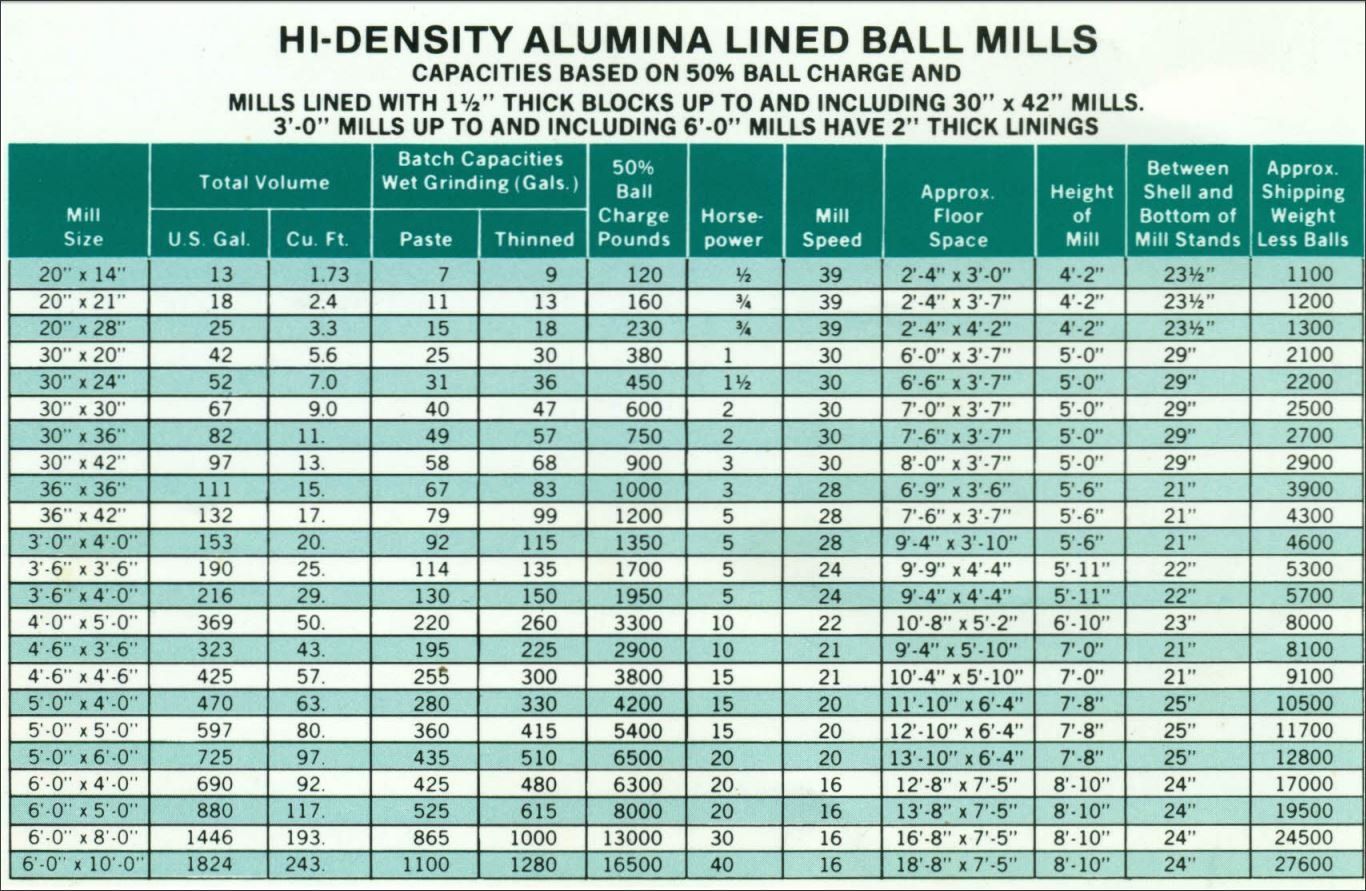

ECONOMY BALL MILLS

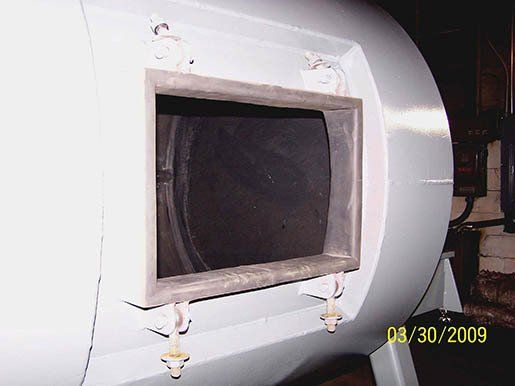

Our standard design Mills use tapered roller bearings mounted on machine turned trunnions, assuring long life and smooth operation. Mill Stands are of fabricated steel allowing for the discharge clearance required by the customer.

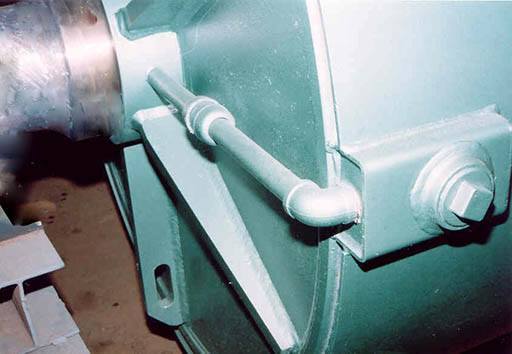

Economy Ball Mills are powered by high start torque motors and, depending on customer preference and design requirements, a direct connect shaft mounted speed reducer or a concentric shaft reducer with a gear and pinion is used to complete the drive train.

Motor Mounted Air Brakes are used when required, for stopping and positioning the mill for charging and discharging. Air Brakes allow for soft stopping, thus reducing shock loading on the drive train.

Stainless Steel Ball Mills

BALL MILL OPTIONS

We have the right ball mill for your needs

GRINDING MEDIA

Available in various sizes and customized to your needs!

At Economy Ball Mill, we offer quality grinding media, steel and ceramic balls for all types of projects; our list of types of balls used in various processes include:

- Carbon Steel

- Carbon Steel Forged

- Stainless Steel

- Ceramic