We Service Internationally!

Fly Ash Ball Mills for Concrete and Asphalt Production

We have been discussing the benefits of using ball mills for fly ash processing, and for good reason!

Fly ash, the fine, powdery substance that remains after coal combustion, presents both a challenge and an opportunity for industries worldwide.

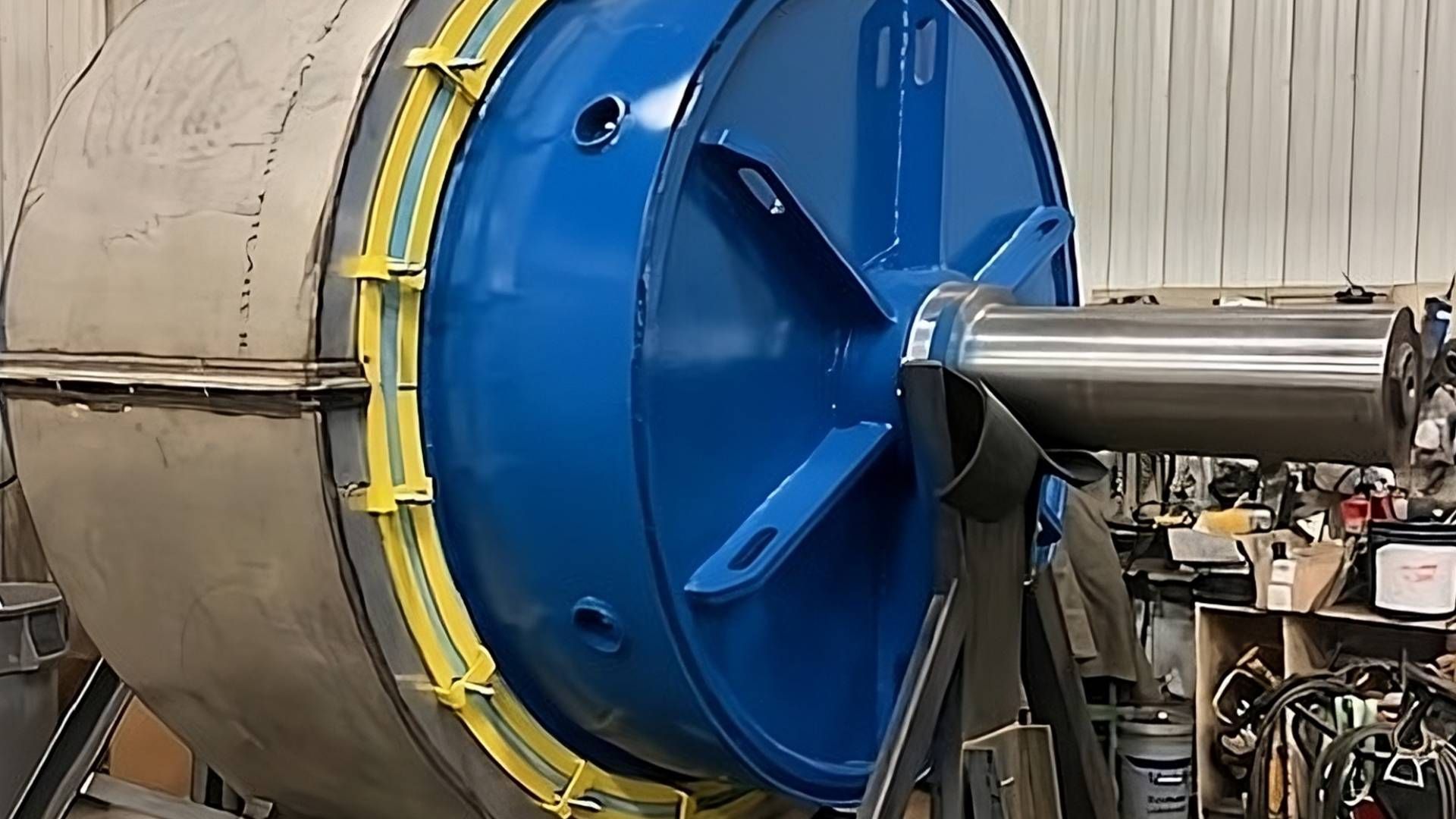

Concrete and asphalt manufacturers are turning to innovative solutions like fly ash ball mills to transform this material—typically considered as waste—into a valuable component of their products. At Economy Ball Mill, we are a leading pioneer in this emerging landscape. Based out of Tollesboro, Kentucky, our team has has been diligently serving businesses with advanced milling solutions.

The Process: Ball Mills for Fine Powder Grinding

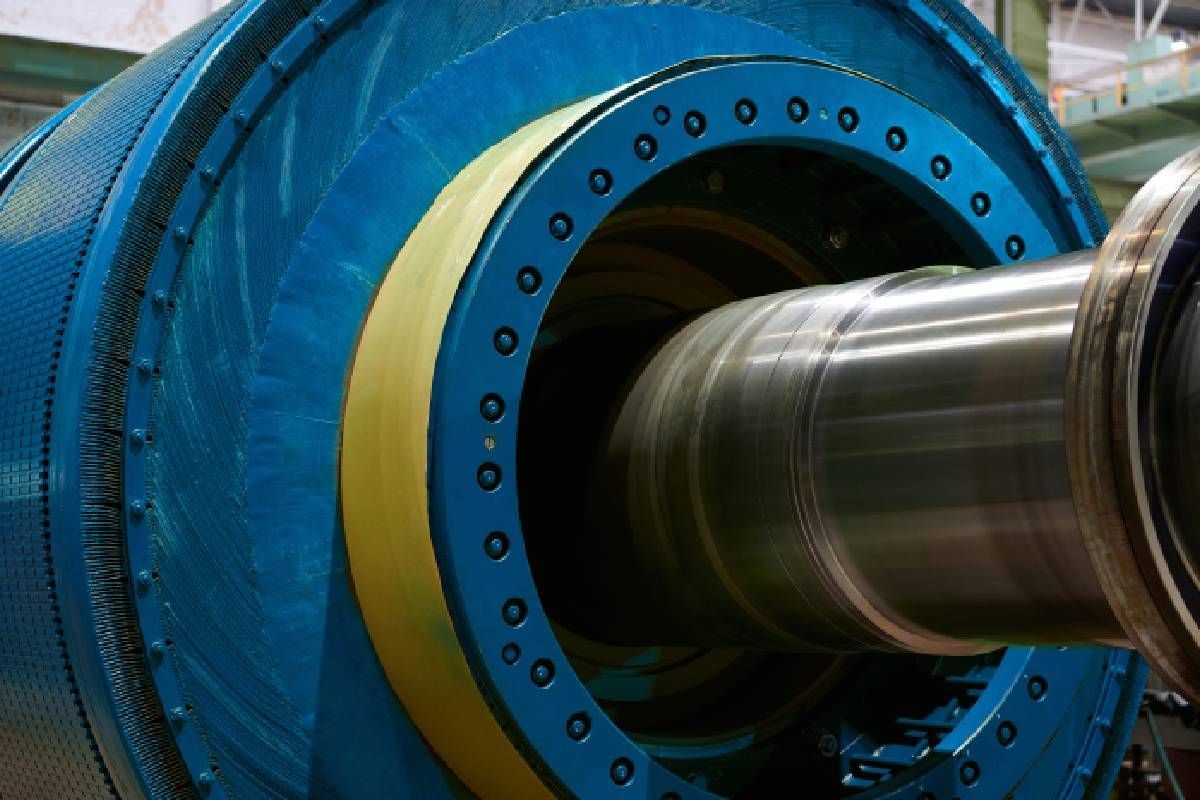

Ball mills operate on a relatively simple principle. In a sealed, cylindrical container, grinding media (balls typically made from steel or ceramic) roll and collide, pulverizing the material into a fine powder. When a ball mill processes fly ash, the resulting product is an ultra-fine ash powder in a more uniform size, perfect for concrete, cement, and asphalt production.

This technique of pulverizing fly ash allows it to react more effectively with other components in the concrete mixture, improving the final product's quality, consistency, and longevity. However, not all ball mills are created equal. The high-quality mills produced by Economy Ball Mill provide efficient and consistent fine powder grinding, making them an excellent choice for companies engaged in concrete and asphalt production.

Unleashing the Power of Fly Ash all Mills

Fly ash might be an industrial by-product, but it becomes a significant resource when treated carefully, especially in concrete and asphalt production. Fly ash ball mills are modern tools used to grind chemicals into powder. In fly ash, these devices serve the crucial function of honing and refining the ash particles, bringing out their latent potential.

Plus, using fly ash for concrete, cement, and asphalt production reduces landfill waste and can be less expensive than other materials, especially for those who already use coal-powered plants so that they can keep their production in-house.

Economy Ball Mill: An Industry Pioneer in Fly Ash Ball Mills

Based in Tollesboro, Kentucky, our team at Economy Ball Mill has served businesses worldwide since its inception. We understand the specific demands and requirements for milling fly ash and other industrial byproducts, and our team can help you find the perfect griding solution for you. Our commitment to quality and dedication to delivering efficient, low-maintenance solutions has led to collaboration with various businesses with varying needs, so you can rest assured that we will treat your order with care.

With Economy Ball Mill's advanced milling tools, businesses can harness the potential of fly ash, turning an industrial by-product into a valuable asset. Ball mills reduces waste, enhances product quality, and fosters a more sustainable approach to industrial production by keeping it close to your business instead of outsourcing it and transporting these materials elsewhere.

Contact Economy Ball Mill for Grinding Solutions

Fly ash ball mills reshape the way we think about waste materials. They transform something seemingly unbeneficial into something valuable, even indispensable, for businesses wishing to modernize their concrete and asphalt production techniques and contribute positively to sustainability efforts. Incorporating fly ash ball mills into their operations stands as an uncompromised solution compared to the many alternatives.

If you're in the market for reliable, high-performance fly ash ball mills, consider contacting our specialists at Economy Ball Mill. We have the experience, dedication, and state-of-the-art ball mills that can help energize your production process, enhance your product quality, and boost your bottom line. Give us a call at (606) 798-5724 to learn more!

All Rights Reserved | JSB Industrial Solutions, INC

Website Design by Creekmore Marketing