We Service Internationally!

Ongoing Dry Flow Processing with a Continuous Ball Mill

In industrial processing, efficiency is a key factor for successful business practice. In industries like mining, manufacturing, and construction, inconsistent processing times and fluctuating product quality can lead to significant operational inefficiencies and increased costs. Choosing more efficient processing equipment can allow businesses to streamline their transportation, storage, and manufacturing processes.

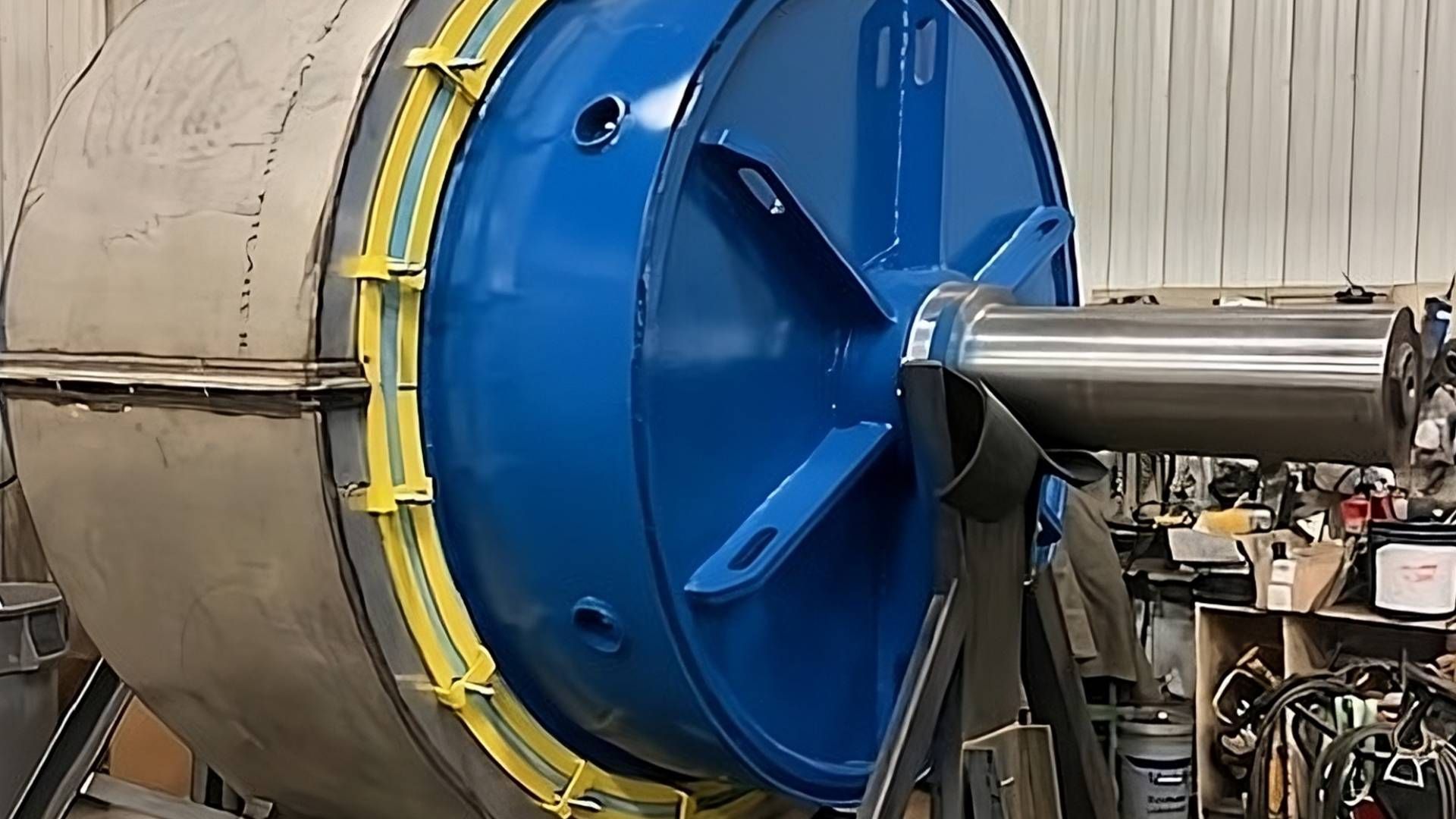

A continuous ball mill is an essential piece of equipment when grinding materials into finer particles. At Economy Ball Mill, we specialize in creating custom ball milling machines that cater to various industries' needs.

In this blog post, we'll explore the concept of ongoing dry flow processing using a continuous ball mill, with a focus on applications such as powder limestone production, ore processing, and manufacturing.

What is a Continuous Ball Mill?

A continuous ball mill is a type of grinding machine that operates nonstop, allowing for uninterrupted material processing. A ball mill operates by rotating a cylinder that holds grinding media and the material to be ground. As the cylinder rotates, the process crushes the material into smaller particles. This steady, uninterrupted process helps maintain consistent size and texture.

Unlike batch ball mills, which process materials in separate loads, a continuous production ball mill enables a constant flow of material through the grinding chamber. Continuous ball mills can support both dry and wet grinding processes. This design offers several advantages, including increased efficiency, consistent particle size, and reduced downtime.

Ongoing Dry Flow Processing for Powder Limestone Production

The production of powder limestone is a common application for continuous ball mills. Various industries use limestone in a powdered form, including construction, agriculture, and manufacturing industries.

The ongoing dry flow processing of limestone in a continuous ball mill offers several benefits:

- Consistent particle size distribution

- High throughput capacity

- Time savings with advanced automation

- Energy efficiency

- Reduced wear on grinding media

Producers can use a continuous production ball mill for powder limestone manufacturing to meet the growing demand for high-quality, finely ground limestone products while minimizing operational costs.

Ongoing Dry Flow Ball Mill for Ore Processing

Continuous ball mills play a crucial role in ore processing in the mining industry, as ores need to be finely ground to release or further process their valuable minerals. The continuous nature of the milling process ensures that ores are ground to the desired particle size efficiently, preparing them for further processing steps.

The ongoing dry flow processing of ores allows for:

- Increased mineral processing rates

- Improved recovery rates

- Reduced processing time

- Lower operational costs

- More efficient use of energy and water

Manufacturing Applications

Beyond powder limestone and ore processing, continuous ball mills find applications in various manufacturing sectors, including cement production, ceramics manufacturing, paint manufacturing, and pharmaceutical production.

In these industries, the ongoing dry flow processing offered by continuous ball mills ensures consistent product quality, increased productivity, and reduced energy consumption.

Advantages of Continuous Ball Mills

- Higher throughput: Continuous production allows for processing larger volumes of material compared to batch operations.

- Improved energy efficiency: The steady-state operation of continuous ball mills results in better energy utilization.

- Consistent product quality: Ongoing dry flow processing ensures uniform particle size distribution throughout the production run.

- Reduced labor requirements: Automation and continuous operation minimize the need for manual intervention.

- Flexibility: Continuous ball mills can be easily integrated into existing production lines or used as standalone units for those starting their own on-house processing programs.

We Can Build Your Continuous Production Ball Mill

Ongoing dry flow processing with a continuous ball mill offers numerous advantages for industries requiring particle size reduction. Whether you're in the business of limestone processing, manufacturing, ore processing, or other industrial applications, a continuous production ball mill can significantly improve your operational efficiency and product quality.

At Economy Ball Mill, we understand the unique requirements of your industry and offer custom ball mills across the USA, Canada, the UK, and worldwide.

Looking to streamline your production process? Contact us online or call (606) 798-5724 to learn more about Economy Ball Mill and discuss your project’s unique needs with a member of our team.

All Rights Reserved | JSB Industrial Solutions, INC

Website Design by Creekmore Marketing