We Service Internationally!

Ball Mills for Better Particle Size Distribution with Air Classifier

In a competitive manufacturing market, businesses are constantly seeking ways to optimize their production processes and reduce costs. We've seen firsthand how combining ball mills with Air Classification Systems can significantly improve particle size distribution, especially in fly ash processing.

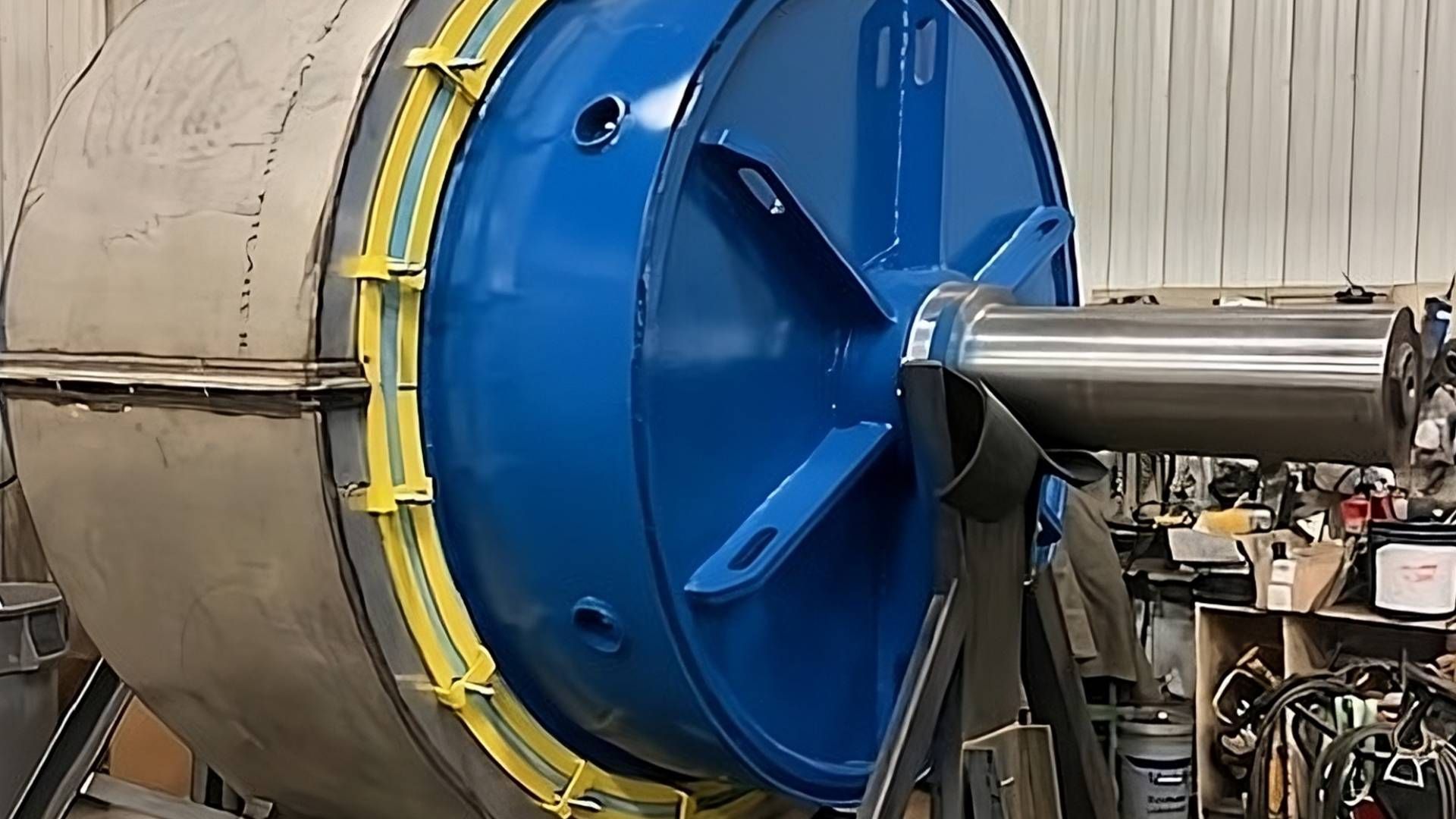

At Economy Ball Mill, we've been providing custom ball mill solutions to clients worldwide, and we look forward to helping you customize a ball mill system for your fly ash processing and beyond.

The Power of Ball Mills in Fly Ash Processing

Ball mills have long been a staple in the materials processing and grinding industry due to their excellent production capabilities and versatility. When it comes to fly ash processing, ball mills excel at reducing particle sizes to meet the specific requirements of its use in creating asphalt and concrete, among other uses. However, the true potential and cost savings of ball mills is unlocked when paired with an air classifier.

Enhancing Particle Size Distribution with Air Classification Systems

Air Classification Systems play a crucial role in achieving optimal particle size distribution by separating materials by size, shape, and density using the power of air and centrifugal mechanics to sort material particles. Here's how the combination of a ball mill and an air classifier can revolutionize your fly ash processing:

- Precise Separation:

The air classifier separates particles that meet size requirements from those that need further grinding. This prevents over-grinding and saves energy, resulting in a more efficient process.

- Improved Consistency:

By continuously classifying particles of fly ash or other materials, an air classifier when used in combination with a

custom ball mill ensures a more consistent particle size distribution in the final product. This is particularly important in industries like construction material manufacturing where precise specifications are critical to how this byproduct is used to create other materials and save waste.

- Increased Throughput:

The combination of a ball mill and air classifier allows for a continuous operation system with less waste, where properly sized particles are constantly removed from the system, increasing overall the output without overprocessing.

- Cost-Effectiveness: The long-term benefits of using a ball mill and air classifier show an improved efficiency and product quality that far outweigh the costs of equipment. This setup helps manufacturers control costs in the face of increasing raw material prices. This process can prevent the waste of materials.

How An Air Classifier System Optimizes Your Fly Ash Processing

When processing fly ash, achieving the right particle size distribution is crucial for the material's performance in various applications, such as materials production or for soil stabilization. The ball mill and air classifier configuration offers several advantages in fly ash processing:

Ball mills can grind fly ash to very fine particle sizes, which are often required for high-performance applications. The air classifier ensures that only particles meeting the size requirements pass through, resulting in a more uniform final product.

By preventing over-grinding, the air classifier helps reduce overall energy consumption in the process. The combination of equipment results in better control of the end product’s size and content in the finished applications, which can enhance the performance of the processed fly ash in various applications.

The Economy Ball Mill Advantage

At Economy Ball Mill, we understand that your manufacturing process is unique. That's why we offer customized ball mill solutions that can be seamlessly integrated with solutions like Air Classification Systems. Our expert team works closely with clients to design a system that meets their specific particle size distribution requirements while maximizing efficiency and minimizing costs—from ball mill development and testing to the manufacturing of your custom ball mill.

We understand how in industrial grinding and particle processing, achieving your optimal particle size distribution is key to producing high-quality products. By combining the grinding power of ball mills with the precision sorting of Air Classification Systems, manufacturers can significantly improve their materials processing capabilities—from fly ash to other manufacturing uses.

At Economy Ball Mill, we're committed to helping our clients achieve better particle size distribution through innovative, custom-designed ball mills. Whether you're in the fly ash industry or any other field requiring precise particle sizing, our team of experts is ready to help you optimize your production process.

Whether you need a standard size or a custom-built ball mill to fit in with your existing air classifier, our team is here to help. Contact us online or call (606) 798-5724 to learn more about how our ball mills can improve your production processes. We serve clients around the world from our site in Tollesboro, Kentucky.

All Rights Reserved | JSB Industrial Solutions, INC

Website Design by Creekmore Marketing