We Service Internationally!

Why You Should Use a Wet Grinding Process

When it comes to industrial milling, depending on the needs of your materials and manufacturing process, one major decision you must make when considering your ball mill needs is whether you need a dry or wet ball mill grinder.

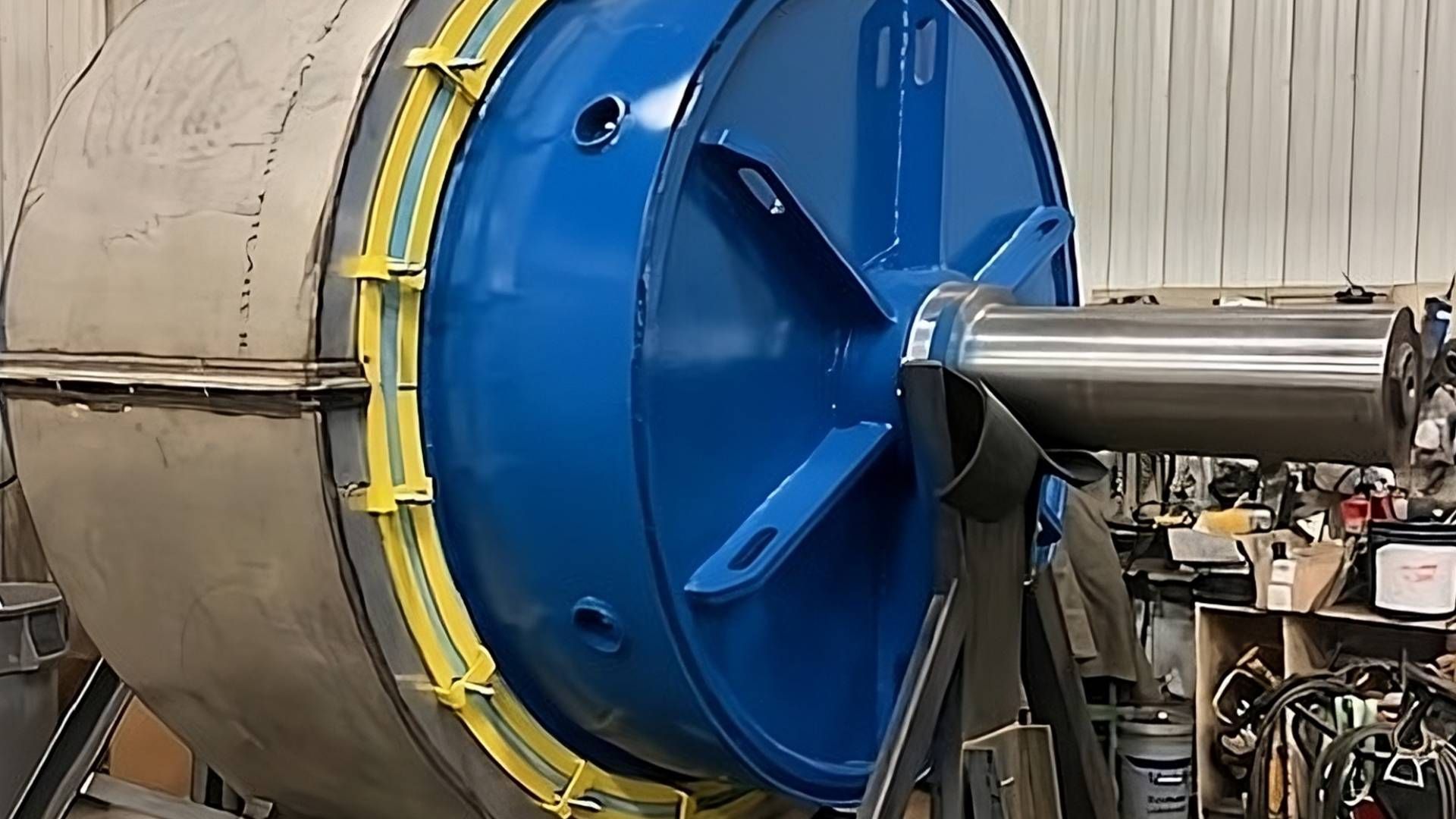

At Economy Ball Mill, our team has worked with businesses across the United States and worldwide to create custom dry and wet ball milling machines for industries across the spectrum, including ceramics, chemical processing, fly ash processing, cosmetics, pharmaceuticals, cosmetics, and many more. We have discussed dry grinding processes in some depth, but equally important is the wet grinding process.

About Wet Grinding with a Custom Ball Mill

At Economy Ball Mill, we've seen a growing interest in wet grinding processes, and for good reason. Wet grinding is a powerful and efficient material reduction method for many manufacturers because it is the ideal choice for certain materials, improves heat management, removes the risks of dust and airborne particle generation, and offers versatility and efficient throughput.

Wet grinding is particularly effective at processing a wide range of substances that might pose challenges in dry grinding. It's also ideal for ceramics, metals, and non-ferrous ore as well as materials that require further processing in a liquid form. However, they are not suited for ores that generate rust or those applications sensitive to moisture that may react with a liquid medium.

Many manufacturing processes require materials in a slurry or suspension form. Wet grinding produces materials in this state directly, eliminating the need for additional mixing steps and simplifying integration with downstream processes. Wet grinding also offers enhanced control over various product characteristics. By adjusting parameters like the concentrated amount of solid material, your chosen grinding media, and grinding time, you can fine-tune your manufacturing properties such as particle size distribution, surface area, and even particle shape.

Enhanced Particle Size Reduction for Materials

One of the primary advantages of wet grinding is its superior efficiency in reducing particle size. The liquid medium in a wet milling machine helps to disperse particles more effectively, preventing agglomeration and ensuring a more uniform particle size distribution. This is particularly beneficial when working with materials that tend to clump together in dry conditions.

Improved Heat Management

Wet grinding excels at managing heat generation during the ball milling process. A liquid medium acts as a coolant, helping to dissipate heat more effectively than in dry grinding. This is crucial for temperature-sensitive materials or when working with substances that might degrade or change properties under high heat conditions.

Dust Reduction for a Safer Working Environment

By nature, wet grinding significantly reduces dust or airborne particle generation compared to dry grinding methods. This creates a cleaner working environment and enhances safety by minimizing the risk of respiratory hazards for workers. If your facility deals with materials that produce harmful or aggravating dust, a wet milling machine could be an excellent solution depending on your material processing needs.

Higher Throughput Capabilities

Wet grinding often allows for higher throughput rates compared to dry grinding. The liquid medium facilitates easier material flow and can handle larger volumes of material more efficiently. This can lead to increased productivity and a timelier output in your manufacturing processes.

When it comes to producing ultra-fine particles, wet grinding is often more energy-efficient than dry grinding. The liquid medium helps to reduce the energy required to break down particles to smaller sizes, making it an excellent choice for industries requiring extremely fine powders.

Learn More About Our Wet Milling Machines

While the choice between wet and dry grinding depends on your specific needs, wet grinding offers numerous advantages that make it an attractive option for many industries. From improved efficiency and safety to better control over product characteristics, a wet milling machine can be a catalyst for your manufacturing processes.

At Economy Ball Mill, we understand the intricacies of both wet and dry grinding processes with our custom ball mills. Our team is ready to help you discover if a wet grinding process is right for your application.

Contact us today to learn more about how our wet grinding solutions can benefit your manufacturing processes. Let Economy Ball Mill help you with creating a custom ball milling machine designed to meet your needs and boost your production efficiency.

All Rights Reserved | JSB Industrial Solutions, INC

Website Design by Creekmore Marketing