We Service Internationally!

Choose the Best Grinding Body for Your Industry

In your business’s industrial manufacturing process, selecting the right grinding body for your operations is crucial. At Economy Ball Mill, we understand that our customers seek efficiency and precision for every step of their production. If you are looking into a custom ball mill, then you know how important the grinding balls can be for particle size reduction.

Maybe you’re considering lead balls for their high density and impact force or opting for ceramic grinding media, known for their durability and resistance to wear. The choice depends on your specific needs.

The Importance of Selecting the Right Grinding Media

When it comes to the use of a ball milli, selecting the appropriate grinding bodies plays a pivotal role in the mechanical reduction of your base materials. That, and time come together and create the exact quality of end product, whether you are seeking a specific weight of fine powders or approximate blend of materials. These elements are crucial in streamlining processes that require the breakdown of solid materials to increase surface area and ensure uniformity, which is essential in industries like mining, pharmaceuticals, ceramics, and manufacturing.

Lead balls are favored in applications where high density and ability to conduct electricity are required. They are instrumental in the pyrotechnic industry and for milling materials unaffected by potential lead contamination. Steel balls bypass this issue while offering a great option for harder materials. On the other hand, ceramic grinding media are ideal for situations where chemical inertness and non-contaminative grinding are crucial. They typically process sensitive compounds where metal contamination must be avoided. Other options like plastic and glass are also used in specific instances as well.

Choosing the Right Material for Your Mill

The choice of grinding media significantly impacts the performance of a ball mill. The material must be compatible with the substance being ground, and the specific properties of each type of grinding body make them suitable for different tasks:

- Lead Balls

- High density for powerful impact

- Effective in applications requiring electrical conductivity

- Ceramic Grinding Media

- Resistant to wear and tear

- Prevents contamination of the milled products

- Steel Balls

- Versatile and generally cost-effective

- Suitable for a range of industrial applications

Each material offers special advantages depending on the nature of the materials processed and the desired outcome.

Customized Ball Milling Solutions for Precise Results

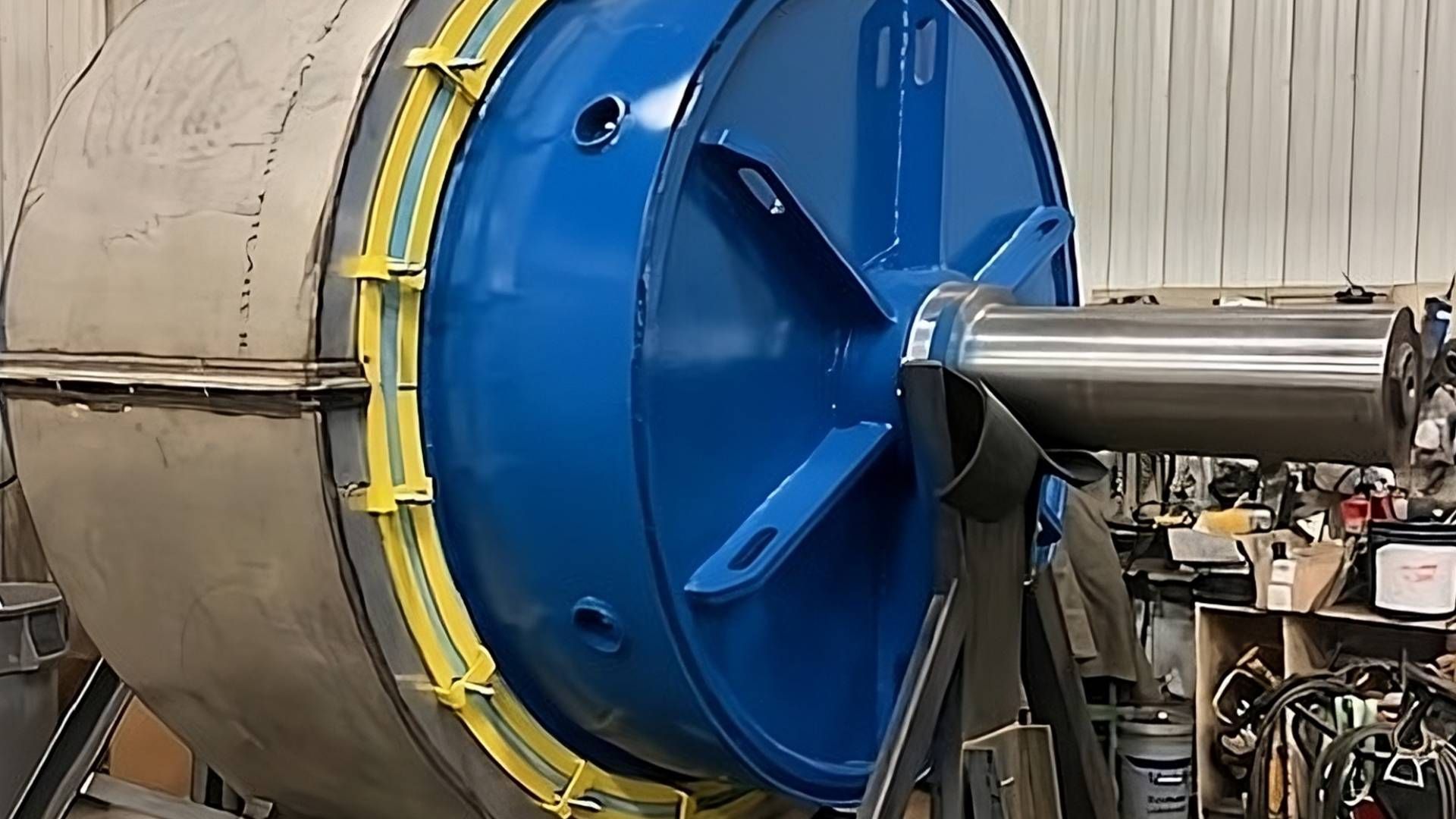

At Economy Ball Mill, we specialize in fabricating custom ball mills to meet the unique needs of our clients, regardless of the batch size required. We pride ourselves on crafting ball milling machines that solve your specific milling challenges. However, it's important to note that we do not provide on-site installation or transport; we ensure that our mills are ready for easy integration into your existing operations.

The Economy Ball Mill Advantage

Our clients come to us with specific needs and trust us for immediate solutions. With years of experience and a deep understanding of the complexities of industrial milling, we offer not just equipment but solutions. Here’s why industry professionals across the world trust Economy Ball Mill:

- Industry Expertise: Our team provides insights and advice on choosing the proper grinding media and mill type for your specific applications.

- Quality and Durability: Our mills use only the highest quality materials and components.

Ready to Optimize Your Materials Processing Operations?

If you're looking for a reliable partner to help optimize your materials processing operations, look no further than Economy Ball Mill. We understand the critical role that grinding media plays in your processes and are here to provide the best options suited to your unique needs. We are your go-to source for high-quality, custom-sized ball mills for clients across the USA and around the world.

Contact us online or call (606) 798-5724 today to discuss your requirements and see how we can help you achieve optimal milling efficiency with suitable grinding media. Let Economy Ball Mill be the solution to your industrial challenges!

All Rights Reserved | JSB Industrial Solutions, INC

Website Design by Creekmore Marketing