Customize Your Ball Mill with Functional Options

When it comes to materials production, you need the right equipment to grind and reduce the size of various materials. Industrial ball mills play an important role in a wide range of industries and help streamline the production process, especially when you order a custom ball mill made to fit the exact specifications of your intended material and industrial needs.

Whether you're in the manufacturing industry, the precious metals industry, food processing, pharmaceuticals, or any application where particle contamination is a concern, selecting the right ball mill is essential.

At Economy Ball Mill, located in Tollesboro, Kentucky, we specialize in providing custom ball mills to businesses all over the world, each individually tailored to your business’s specific needs.

Stainless Steel Ball Mills: A Contamination-Resistant Choice

In certain industries, maintaining the purity of the processed materials is of utmost importance. This is where stainless steel ball mills come into play. Stainless steel balls are resistant to breakdown, making them ideal for applications where contamination is a concern.

- Food grade and pharmaceutical applications: Stainless steel balls are also preferred in food grade and pharmaceutical applications. Regulatory bodies like the FDA and USDA are often involved in these industries, and they have stringent requirements for purity.

Industries like precious metals even measure contamination in parts per million (PPM). Choosing stainless steel ball mills and stainless steel grinding media can help ensure that the final product remains uncontaminated, making it the preferred choice, especially in dry milling applications, with the correct ball-to-powder ratio.

In wet grinding applications, ceramic grinding balls make a great option for grinding media because they avoid rust and corrosion in aqueous mediums.

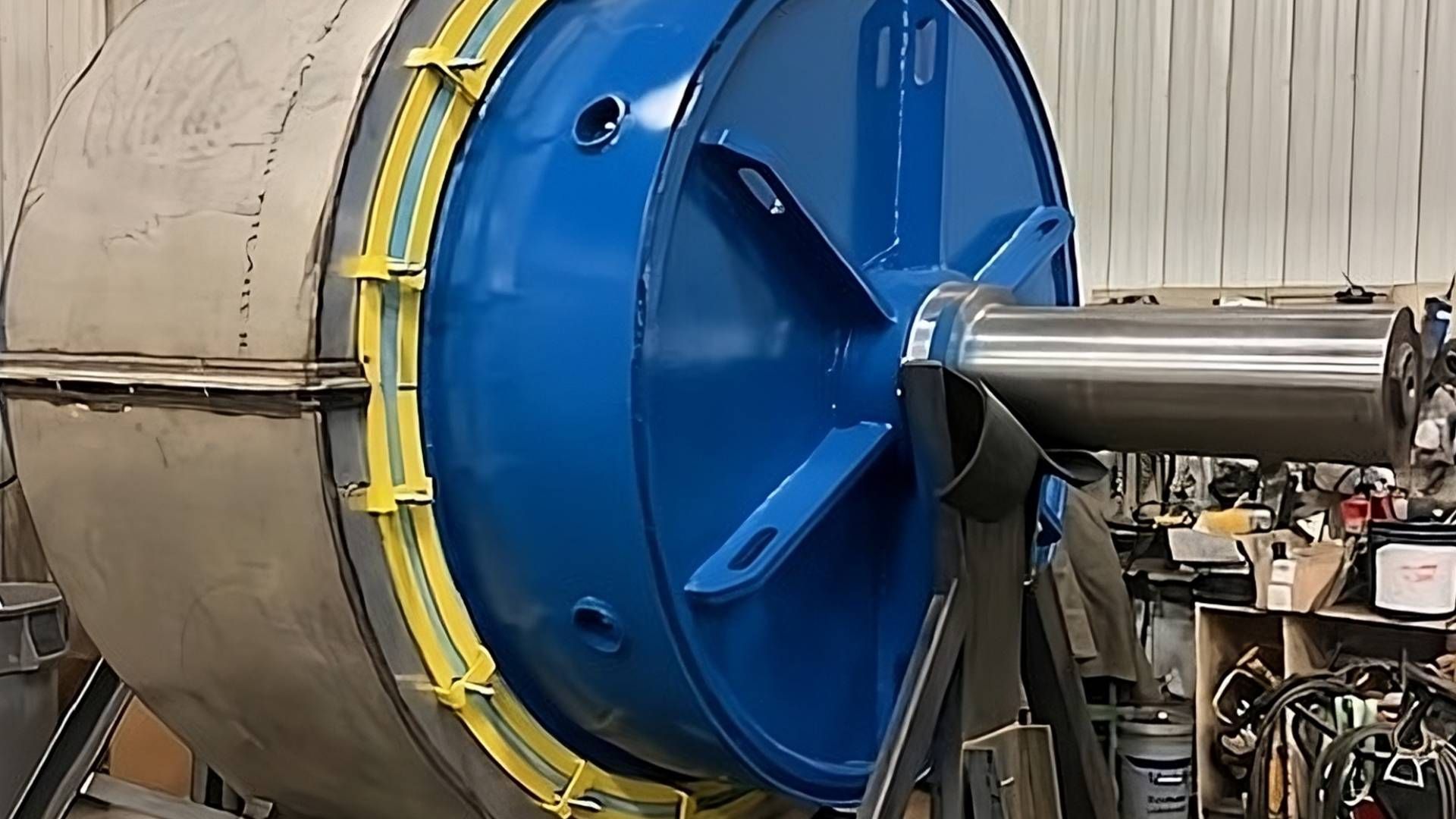

Unlined Steel Ball Mills: Tough and Reliable

We offer unlined steel ball mills fabricated from AR 400 abrasion-resistant steel. These mills are known for their toughness and reliability. They are generally provided with welded or bolted lifter bars, ensuring efficient grinding of materials.

Alumina Lined Ball Mills: High Density Protection

For applications requiring extra protection against wear and abrasion, Economy Ball Mill provides steel cylinders lined with 2-inch-thick high-density Alumina tongue and groove brick. These bricks are secured using standard Portland cement or epoxy mortar for special applications where carbon is a potential contaminate and/or color is an important part of the finished product of grinding. This Alumina lining offers exceptional durability and extends the lifespan of the ball mill.

Rubber Lined Ball Mills: Resilience and Impact Absorption

If you need a ball mill that minimizes the impact and abrasion of the materials being processed, Economy Ball Mill offers rubber-lined ball mills. These steel cylinders are lined with abrasion-resistant natural rubber, providing resilience and impact absorption. This option is ideal for applications where the material being ground can be particularly abrasive or susceptible to damage.

International Service and Support

Economy Ball Mill is not limited to serving customers in the United States. We proudly offer our products and expertise internationally, willing to provide custom ball mills anywhere you need them. This commitment to accessibility means that no matter where your business is located, you can benefit from our top-notch ball mill solutions.

Get Started with Economy Ball Mill Today

If you’re in the process of selecting the right ball mill for your specific application, Economy Ball Mill provides a range of options to meet your needs. Whether you require stainless steel for purity, abrasion-resistant steel for toughness, high-density Alumina brick lining for durability, or rubber lining for impact absorption, we have the expertise and experience to deliver the perfect custom ball mill solution.

With our commitment to quality and international service, our ball mill experts at Economy Ball Mill are your trusted partner in the world of grinding and material reduction.

For more information and to explore our products, browse our website and contact us to learn more today.