Using Ball Mills for Fly Ash Processing

In a world where companies are more aware than ever of their environmental impact, fly ash is often dismissed as an industrial by-product of coal-fired power plants. But with the right handling and processing, fly ash can be converted from a waste product into a valuable commodity that is in demand for construction, landscaping projects, and more.

At Economy Ball Mill, we’re a Kentucky-based company making its mark in the worldwide ball mill marketplace. We serve the fields of industrial processing and manufacturing. At the heart of our service is an unwavering commitment to customer satisfaction and an expertise in ball mills.

Choose Our Ball Mills for Fly Ash Processing

Being deeply rooted in this industry for years, Economy Ball Mill has developed a wide variety of applications for our versatile ball mills. One such application we're proud to highlight is ball mills for fly ash processing.

Ball mills play an indispensable role in transforming the heavy flue-gas residues, also known as fly ash or coal ash. You can use a ball mill to transform this material into a lightweight aggregate that can be mixed into concrete or cement used in construction.

From Waste to a Valuable Commodity

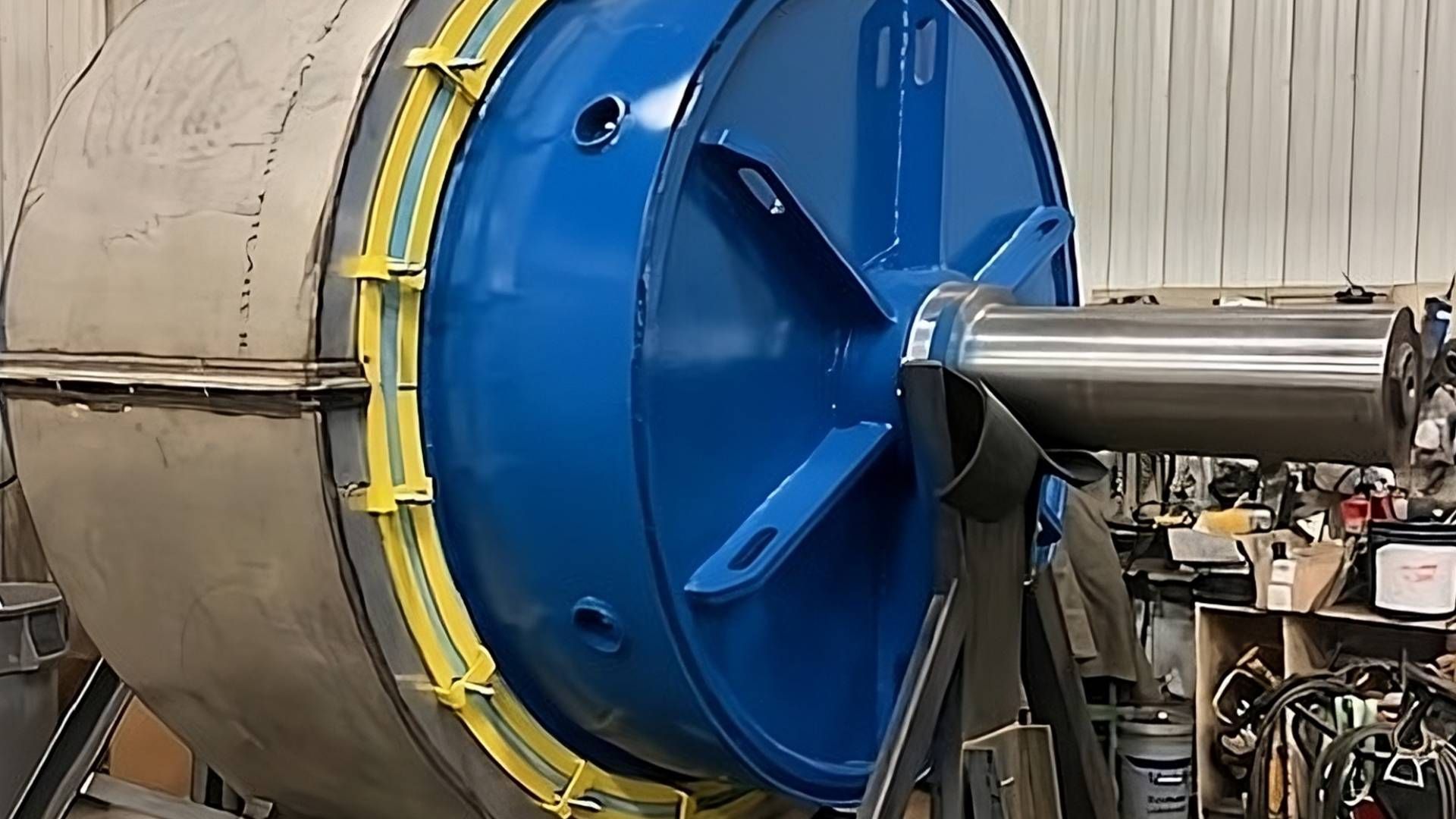

A key tool for making this transformation possible is a ball mill. In the simplest terms, a ball mill is a cylinder that's filled with steel balls or other grinding media. The mill's job is to grind and crush the fly ash into a finer material that can be used in other industrial processes, or it can be mixed with cement and used in construction projects.

Here is where Economy Ball Mill makes a difference. Our ball mills are designed with efficiency, cost-effectiveness, and durability in mind. With superior engineering and manufacturing capabilities, our ball mills are the ideal solution for fly ash processing.

Unmatched Efficiency

Our ball mill designs offer unmatched efficiency in terms of energy consumption, meaning they're not only good for your bottom line, but also for the environment. This efficiency translates to less time in processing the fly ash and more output, benefiting both your business’s productivity and adding to your profit margins. Additionally, the material output resulting from our ball mills is easier to include in the construction materials than other media, providing a higher quality and less costly end-product to your customers.

Cost-effective and Durable

Economy Ball Mill’s products have been constructed to last, making them a cost-effective ball mill solution for the long-term. Moreover, we provide reliable aftermarket services and support like attritor mill barrel rebuilds to ensure your machinery is always operating at optimal levels.

Contact Us For Ball Mills for Fly Ash Processing

Fly ash can be turned into more than just an industrial by-product. With economically effective and environmentally sound strategies for processing, like those provided by Economy Ball Mill and our state-of-the-art ball mills, fly ash can become a valuable commodity in the industrial and construction marketplace.

Here at Economy Ball Mill, we are proud to contribute to this innovative, sustainable solution for dealing with fly ash. Contact us online or give call us at (606) 798-5724. Our team is standing by to take your business to the next level with mall bills from Economy Ball Mill.