We Service Internationally!

Understanding Dry Grinding: Key in Material Size Reduction

If you’re looking for a way to reduce the size of your materials, you may have come across the terms wet grinding and dry grinding. These are two different methods of milling that have their own advantages and disadvantages.

Depending on the material you’re processing and the application of how you plan to use this material, dry grinding may be the best option for your needs. When you work with Economy Ball Mill, you can trust that our team will be able to help you find the perfect ball mill as a solution for your materials processing needs.

Read on as we discuss the dry grinding process and how it differs from wet grinding:

Wet Grinding vs. Dry Grinding

Wet grinding is a process that involves dispersing the raw material in a liquid and circulating it through a grinding chamber. The particles are crushed by the grinding media, which are usually small balls or beads made of ceramic, metal, or other materials.

Wet grinding can achieve very fine particle sizes but requires more energy, time, and equipment than dry grinding. Wet grinding also produces waste liquid that needs to be disposed of or recycled.

Dry grinding, on the other hand, is a more straightforward process that uses particle-on-particle impacts to reduce the size of the material. The raw material travels within a contained area and either collides with other particles or strikes against machine components, such as rotors or blades.

Dry grinding can be done in a single pass or in multiple passes, depending on the desired fineness of your finished material. Dry grinding requires no liquid, meaning less waste, lower costs, and easier maintenance.

Benefits Of Dry Grinding

Dry grinding has many benefits over wet grinding, especially for certain applications and industries.

Some of the benefits of dry grinding are:

- It can handle heat-sensitive materials that degrade or change properties in wet conditions.

- It can produce uniform and consistent particle sizes and shapes, improving the final product's performance and quality.

- There aren’t as many contamination risks since no liquid carries impurities or bacteria.

- It can save energy and water resources because there is no need to heat, cool, or pump liquids.

- You’ll reduce the environmental impacts since there is no liquid waste to treat or dispose of.

Dry Grinding Solutions from Economy Ball Mill

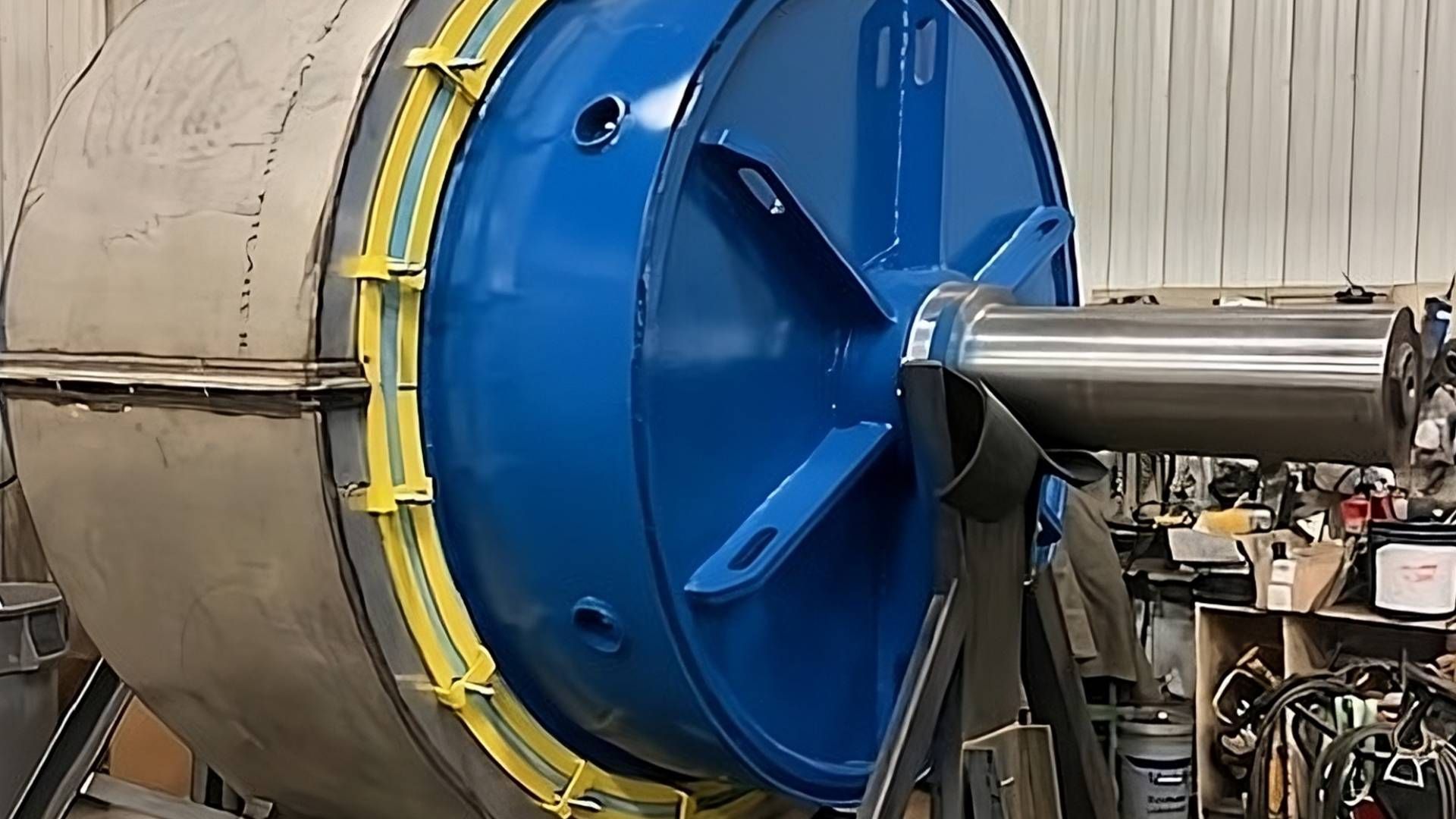

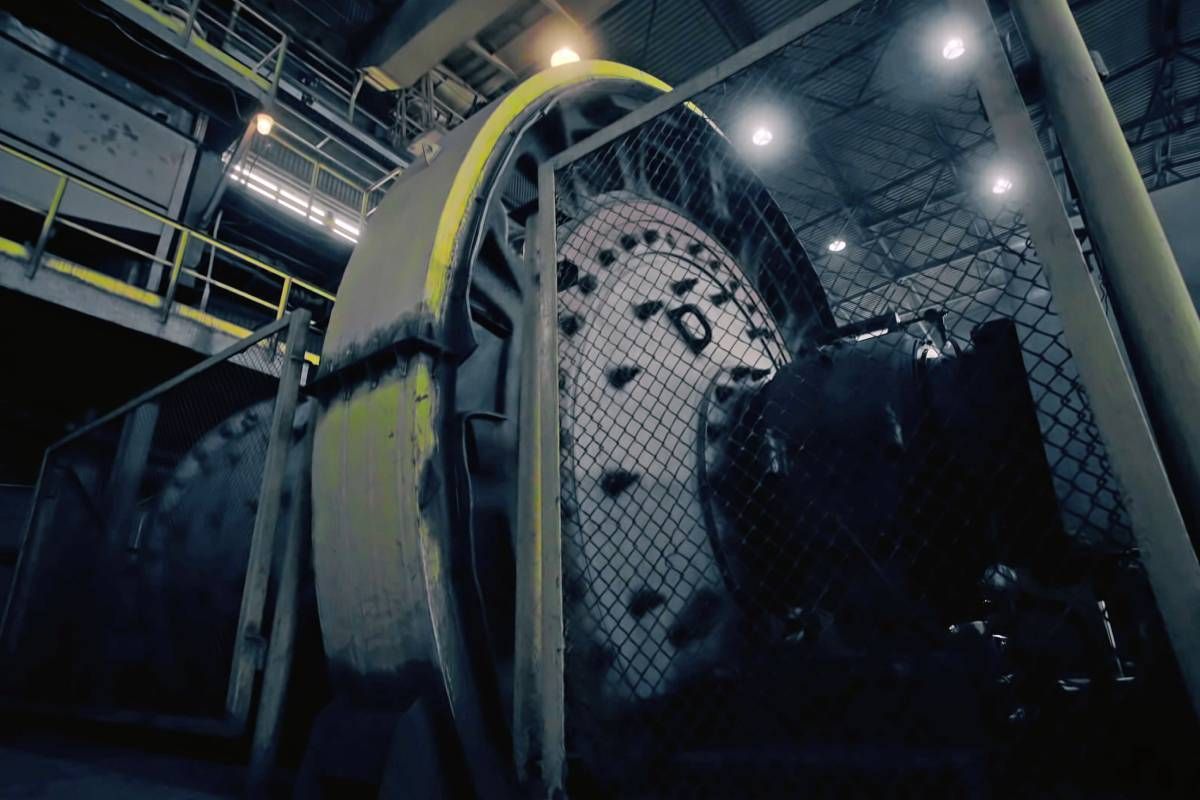

If you’re looking for a reliable and efficient dry grinding solution, look no further than Economy Ball Mill. We are a leading manufacturer of custom ball mills that can handle any size-reduction challenge.

Our ball mills are designed to meet your specific needs and specifications, whether you need a small batch mill or a large-scale production mill.

Our ball mills use products and metal balls that make your material come out as a finer powder. Our ball mills can grind various types of materials, such as:

- Minerals

- Ores

- Chemicals

- Pigments

- Paints

- Ceramics

Many suitable industries need size reduction for their materials, such as mining, cement, pharmaceuticals, cosmetics, food processing, and more.

We’re in Tollesboro, Kentucky, but we serve customers worldwide. We can ship our products anywhere you need them. We also offer excellent customer service and support to ensure your satisfaction.

To learn more about our dry grinding solutions and how they can benefit your business, visit our website or contact us today.

Get Started with Economy Ball Mill Today

At Economy Ball Mill, we’re a leading manufacturer of custom-made ball mills for various industries. We have many years of experience in designing and producing high-quality ball mills that can meet your specific requirements. We can provide both dry ball mills and wet ball mills, and can complete attritor mill barrel rebuilds.

We’re based in Tollesboro, Kentucky, but we serve customers worldwide. We do not offer on-site installation or transport of our products, but we can ship them anywhere you need them.

If you are interested in our products or services, please contact us online or call us at (606) 798-5724. Our team is standing by to take your business to its next level with mall bills from Economy Ball Mill.

All Rights Reserved | JSB Industrial Solutions, INC

Website Design by Creekmore Marketing